Hopes for Akadama soil

The Significant Issue

Prosarich has recognized a significant issue related to the supply of hard Akadama soil, a vital component for bonsai and succulent cultivation. The global demand for hard Akadama soil has been on the rise due to the bonsai and succulent booms, but supply has been limited. The key challenge is that the naturally occurring Akadama soil in the area near Mt. Nantai is too soft for bonsai and succulent use.

Solution

To address this issue, Prosarich has introduced a solution by firing Akadama clay at a high temperature (about 300°C) for 20 to 60 minutes in a rotary kiln.

This process transforms the clay into hard Akadama soil, making it a valuable and sought-after product for the global horticultural market. Prosarich's goal is to supply hard and high-quality Akadama soil all over the world, meeting the increasing demand from bonsai and succulent enthusiasts.

Process 1 | Where does AKADAMA soil come from?

Mine & Dry

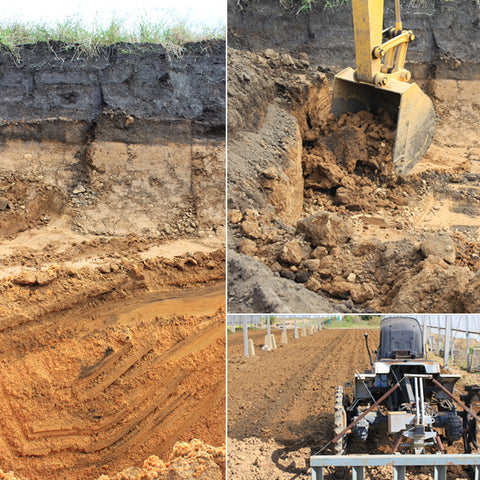

A mining site in Mibu Town, Shimotsuga District, Tochigi Prefecture.

The black one is black soil, below that is red soil (the raw material for Akadama soil), and below Akadama soil is Kanuma soil.

Black soil 60cm, red soil 90cm, Kanuma 150cm. The reason Akadama soil is more expensive than Kanuma soil is because the layer is not as thick as Kanuma soil.

Let it dry in the sun for about a week in a greenhouse.

Once the surface is dry, turn it over with a tractor to speed up drying.

Process 2 | Where does AKADAMA soil come from?

Crushing

Transport the dry soil to the factory.

Fill the hopper with soil and place it on the conveyor belt.

Take it to the crusher.

Grind the lumps into large, medium and small pieces using a grinder.

Process 3 | Where does AKADAMA soil come from?

Getting rid of the finer soil particles & Sorting by size

The crushed Akadama soil is transported to a powder removal machine.

The powder is collected in three batches, and only the powder is transferred to another location using a conveyor.

The powder cannot be made into Akadama soil products. The powder is used as a raw material and sold for other purposes.

Put the powder-free Akadama soil through a sieve machine.

Separate the sizes based on the size of the net. They are divided into fine grains, small grains, medium grains, and large grains.

These are put into the hopper of a rotary kiln and baked.

Process 4 | Where does AKADAMA soil come from?

Baking & Bagging

Bake in a rotary kiln.

The powder is removed again and sent to the

bagging machine.

The bags are packed using a bagging machine,

sealed, and sent to a pallet robot.

A palletizing robot stacks the items on pallets

from side to side.